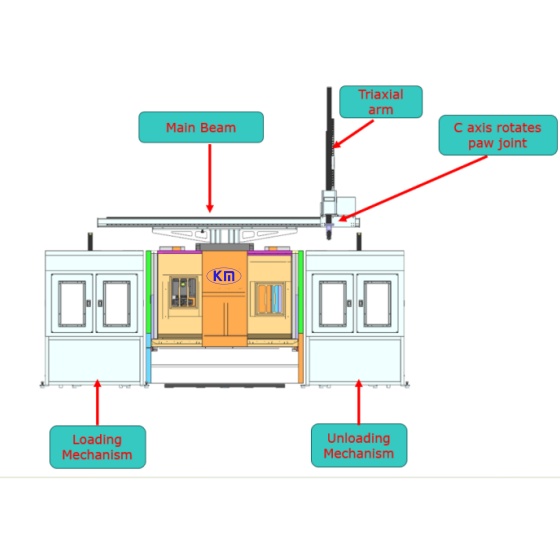

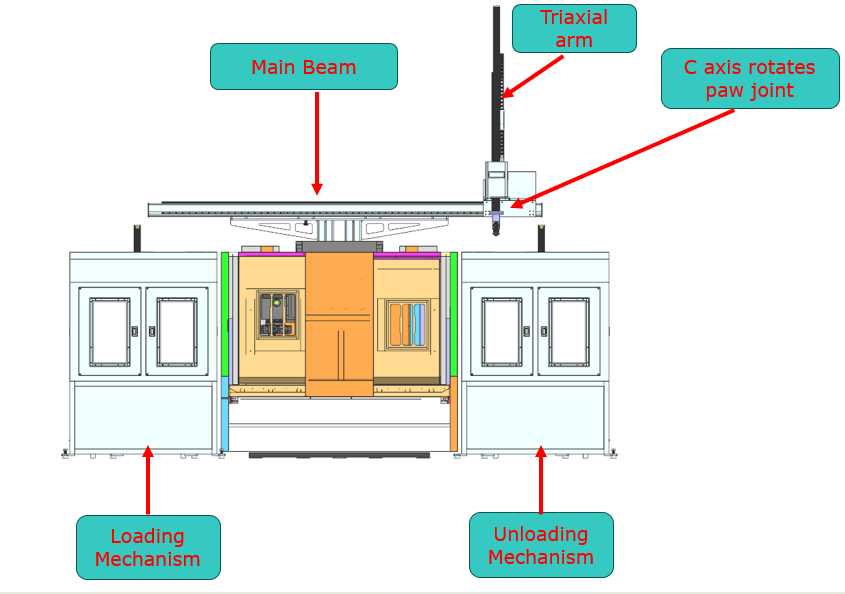

1.Manually push the designated material frame into the loading area in advance;

2.The material rack automatically sorts the parts inside the material frame and positions them;

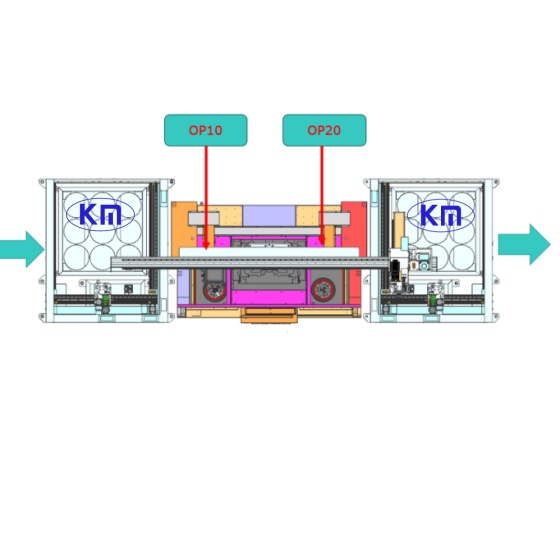

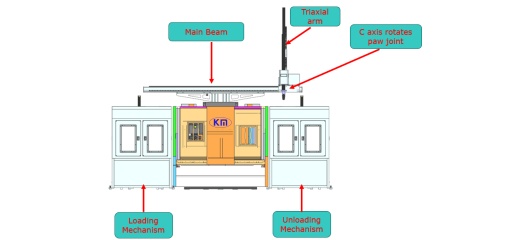

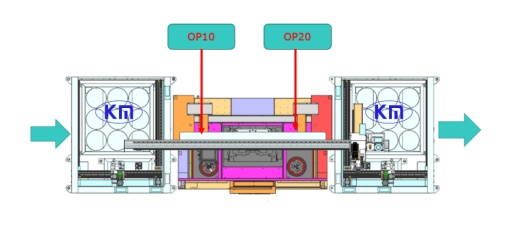

3.The truss manipulator grabs the positioned parts and moves them to OP10 to wait;

4.After the standby bed completes processing, send a signal to the truss manipulator;

5.The truss manipulator needs to replace parts, first remove the parts, then install new parts, and start the machine tool processing;

6.The truss manipulator moves to the transfer platform, performs secondary positioning and flipping of the parts, and then grabs the parts;

7.The truss manipulator grabs the parts inside the transfer platform and moves them to OP20 to wait;

8.After the standby bed completes processing, send a signal to the truss manipulator;

9.Replace the parts of the truss manipulator, first remove the processed parts, then install new parts and start the machine tool;

10.The truss manipulator moves the cutting mechanism and places the extracted parts on the receiving platform;

11.The material rack automatically arranges the processed parts in an orderly manner;

12.The truss manipulator returns to the feeding mechanism and grabs the positioned parts again;

.jpg)

.jpg)

.png)

.png)